COMET CENTRIFUGAL PUMPS

Where high water-rates are required, generally used on a self propelled machine with Hydraulic systems.

HYDRAULIC CENTRIFUGAL PUMP C610H

Pump body in cast iron with cataphoresis treatment.

Polyamide rotor, Graphite-Silicon-Viton® mechanical seal.

COMET C610H

MAIN BENEFITS

1. Orientable pump with four positions at 90°.

2. Foot fastened horizontally to the crankcase in any pump position.

3. Techno-polymer rotor with high chemical and mechanical resistance.

4. Separate pump-motor flanging for quick and easy maintenance.

HYDRAULIC MOTOR VERSION

... did you know... ?

ABOUT CENTRIFUGAL PUMPS

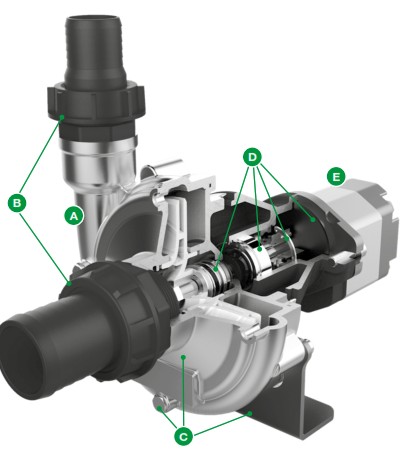

A.EXTREME RESISTANCE

Pump crankcase in cast iron with cataphoresis coating (C610H).

B.VERSATILITY

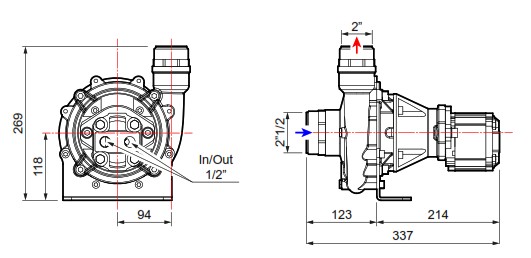

Straight or elbow inlet (Ø 50 mm)/delivery (Ø 60 mm) fitting. Available also in 2″ clamp coupling ( 1 ).

C.ORIENTABLE

Pump can be installed in four positions at 90°. Water drain and air bleeder in each of the four pump positions.

The foot is horizontally fastened to the crankcase in any pump position, with stable and independent fixing for maintenance purposes.

D.OUTSTANDING MATERIALS

Techno-polymer rotor with high chemical and mechanical resistance. Long-lasting Graphite-SiliconViton®mechanical seal. Pump shaft with double bearing. Splined motor shaft guaranteeing quick and simple coupling to the pump hollow splined shaft. Separate pump-motor flanging for quick and easy maintenance.

E.HIGHEST PERFORMANCES

Gear motor (higher performance than Gerotor).

• Flange SAE A – 2 holes

• Shaft SAE A – 9T

• Rear couplings

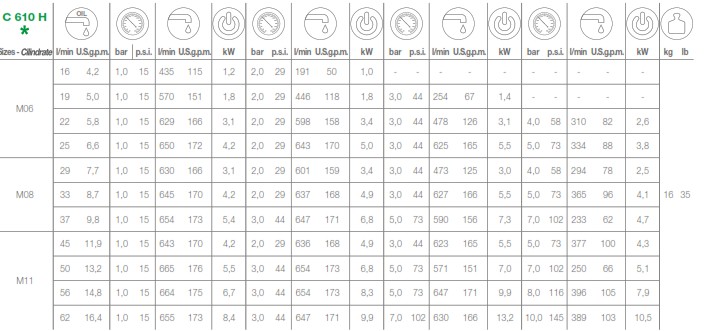

• Available in 3 different sizes (M06, M08, M11)