COMET SERIES BPS

Up to 20b, excellent and reliable, especially for boom-spraying in broad-acre situations.

OVERVIEW

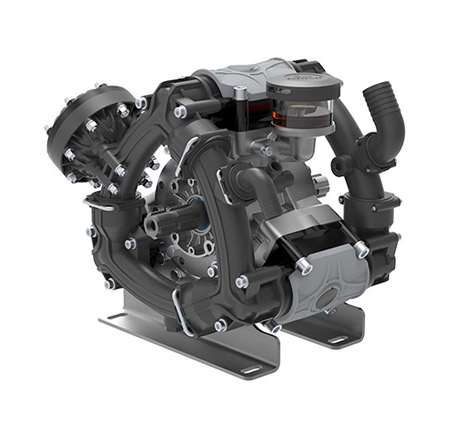

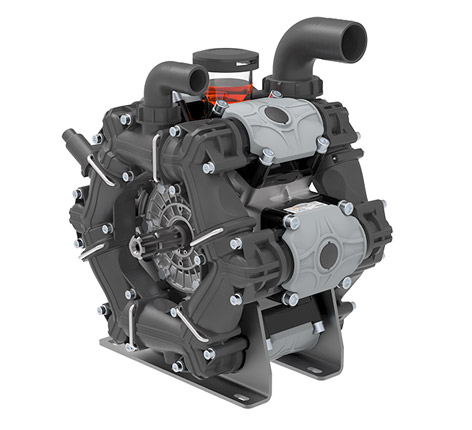

The BPS line boasts a series of major features unparalleled on the market: reduced overall dimensions, ease of maintenance, long life and resistance to heavy duty operating conditions, while always providing high performance in terms of flow rate, priming capacity, power absorption and silent running.

The BPS range includes 8 pumps with 20-bar max pressure and flow rates from 162 to 382 l/ min, designed for the most modern and high-performing boom-sprayers.

All the pumps of the BPS range can be coupled in tandem to increase flow rates or obtain multi purpose synchronous applications (spraying /agitation/constant recirculation).

What is more, to optimize the after-sales service, most of the spare parts are shared across the range.

HIGHLIGHTS

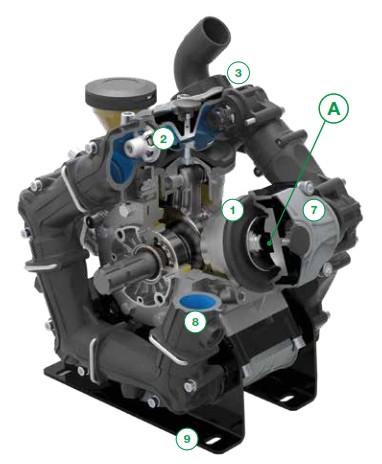

A.LOW-MAINTENANCE

The combination of over-sized diaphragms and reduced piston stroke provides maximum durability for diaphragms, check valves and consumables. The drain plugs are present on both manifolds to help prevent icing and related issues.

B.PERFORMANCE

This same combination of short-stroke pistons, oversized diaphragm ( 1 ) and check-valves ( 2 ) with innovative fluid slots and spring loads, allows for a unique priming capacity, flow-rate accuracy and shut-off speed.

C.MODULARITY

These pumps can be coupled in “tandem” to expand the flow-rate or for multi-purpose applications.

D.VERSATILITY

Hose barbs available in fly-nut threaded (3) or clip/fork coupling version (4).

On Request, shaft plugs available in 1” 3/8 splined M or F (5); 25 or 32 Ø mm F ( 6 ).

E.OUTSTANDING MATERIALS

Plastic-coated aluminum heads ( 7 ). Stainless steel -techno-polymer check-valves. Manifolds and fittings in high tech polymers ( 8 ). Double-coated steel-made holders ( 9 ). Diaphragms in Desmopan.

OUR RANGE

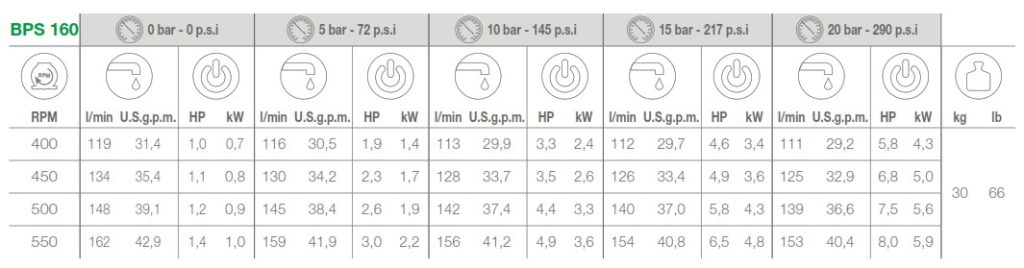

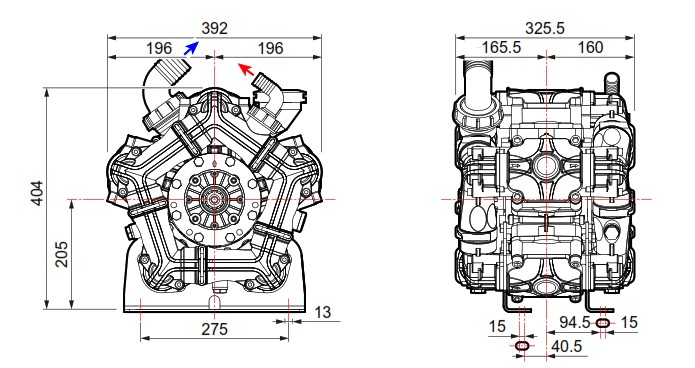

COMET BPS160

LOW PRESSURE DISPAHRAGM PUMP BPS160

Configuration: 3 diaphragms in Desmopan® (Viton available on request).

Parts in contact with spray liquid: plastic coated aluminium and polyamide.

Standard: pressure accumulator. (MOUNTING BRACKETS)

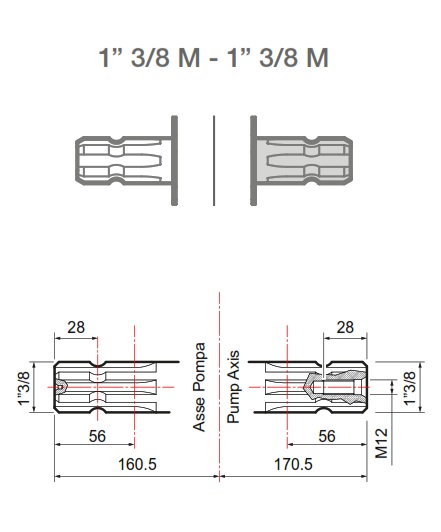

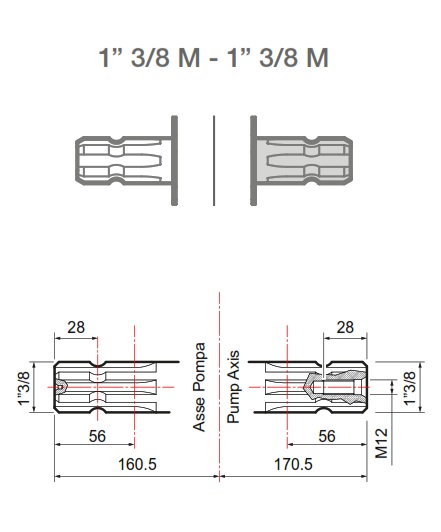

SHAFT : THROUGH 1⅜M-1⅜M

MAIN BENEFITS

1. Over-sized diaphragms.

2. Short-stroke pistons.

3. Pumps can be coupled in “tandem” to expand flow rate capacity or multi-purpose applications (spraying/agitation/rinsing/constant recirculation).

4. Plastic-coated aluminum heads. Stainless steel-techno polymer check-valves.

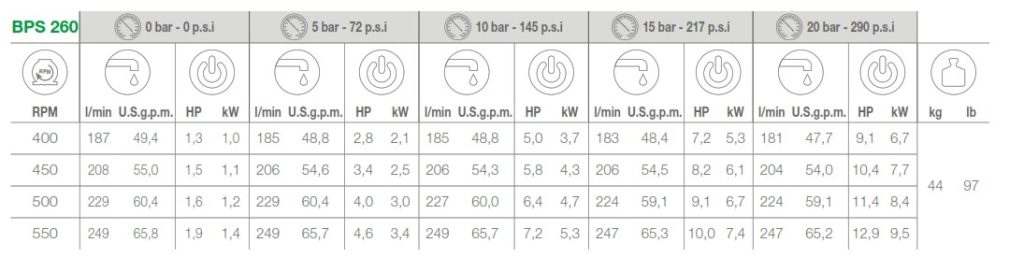

COMET BPS260

LOW PRESSURE DISPAHRAGM PUMP BPS260

Configuration: 5 diaphragms in Desmopan®.

Parts in contact with spray liquid: plastic coated aluminium and polyamide.

Complete with Feet (MOUNTING BRACKETS)

SHAFT : THROUGH 1⅜M-1⅜M

MAIN BENEFITS

1. Over-sized diaphragms.

2. Short-stroke pistons.

3. Pumps can be coupled in “tandem” to expand flow rate capacity or multi-purpose applications (spraying/agitation/rinsing/constant recirculation).

4. Plastic-coated aluminum heads. Stainless steel-techno polymer check-valves.

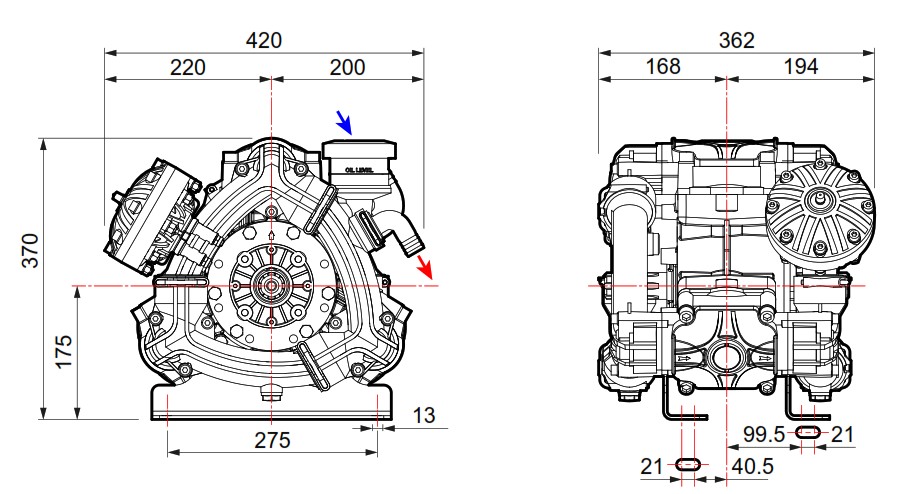

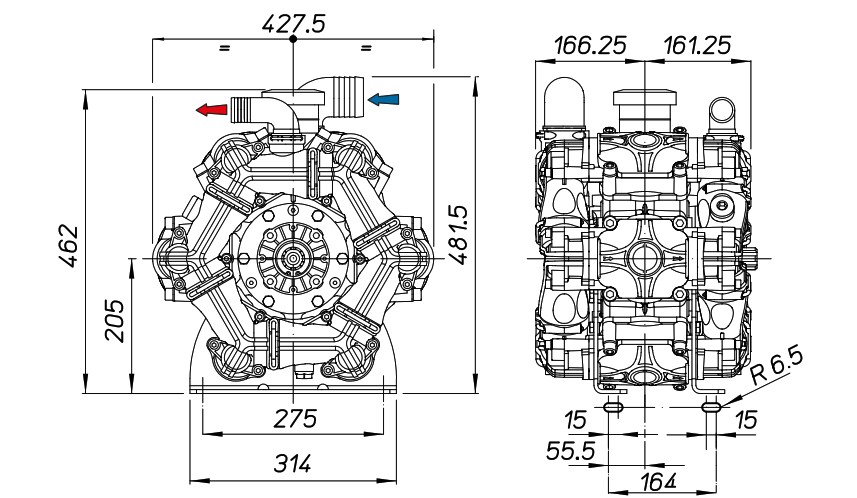

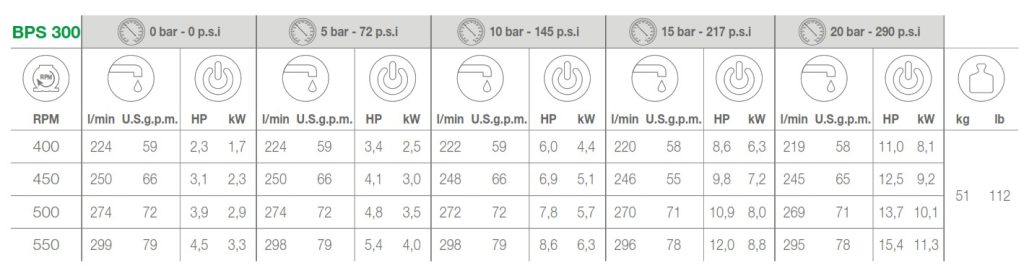

COMET BPS300

LOW PRESSURE DIAPAHRAGM PUMP BPS300

Configuration: 6 diaphragms in Desmopan® (Viton available on request).

Parts in contact with spray liquid: plastic coated aluminum and polyamide.

Complete with Feet (MOUNTING BRACKETS)

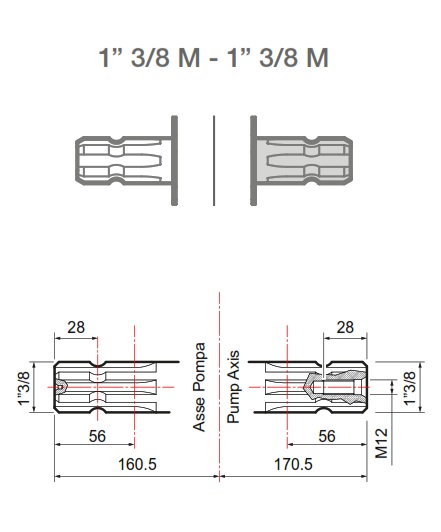

SHAFT : THROUGH 1⅜M-1⅜M

MAIN BENEFITS

1. Over-sized diaphragms.

2. Short-stroke pistons.

3. Pumps can be coupled in “tandem” to expand flow rate capacity or multi-purpose applications (spraying/agitation/rinsing/constant recirculation).

4. Plastic-coated aluminum heads. Stainless steel-techno polymer check-valves.

AN EXAMPLE OF TANDEM SET UP

BPS series pumps are couplable in “tandem” to expand flow rate capacity or multi-purpose applications (spraying/ agitation/constant recirculation).

SPARE PARTS AVAILABLE

We carry a significant amount of spare parts in stock. Contact us to order yours.